|

| 3-D Modeling of saucer design |

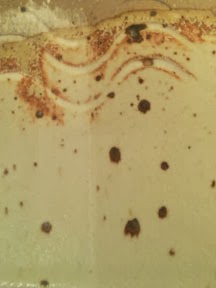

Many very pretty glazes, unfortunately, are plagued by a horrible amount of running. Crystalline glazes, Ox Bloods, Chuns, Rutile Blues, and other various types often can run off the pots that they are on. Personally, my Shorn Base and Permafrost Base (if fluxed by a high amount of colorant) run a lot. This gives me good reason to use saucers, like crystalline glaze potters use, under my pots. The average design, however, for these saucers is just a flat shallow bowl which would then easily fuse the piece to the saucer quite often.

So, I designed a saucer that I believe could catch all of the glaze dripping, be reusable, and easily made from a press mold. That means that i could easily and quickly make new saucers if one does happen to not be reusable after a firing. By setting the pot on a tripod of points, rather than on the surface of the saucer, the liquid glaze can freely drip down. Higher gaps between points would be smart for larger pots.

There are a few risks that could be possible with this design though: if the kiln is violent (such as wood, soda, or salt) the pot might fall off the saucers or if the pot has an excessively thin base and is very soft at high temperatures it could create dimples on the bottom of the piece.

These should be made from a hard, porous clay and cover in kiln wash on the top surface including the points and rim. With the kiln wash, removing glaze drips would be easier making these saucers last for more firings. Any glaze left on the saucer would just melt again in the next firing - eventually leading to a glaze overflow.