|

| MC Spodumene Custer Feldspar - 30 EPK - 28 Whiting - 5 Dolomite - 25 Spodumene - 10 Tin Oxide - 2 |

|

| Permafrost +10% Rutile Neph Sye - 45 Flint - 30 Whiting - 8 Dolomite - 10 Talc - 7 -------------------- Rutile - 10% |

|

| Permafrost +2% Cobalt Carb Neph Sye - 45 Flint - 30 Whiting - 8 Dolomite - 10 Talc - 7 -------------------- Cobalt Carb - 2% |

The Permafrost base is a opaque satin white without colorants. It runs slightly, and more so with added oxides. Exceeding 3.5% Red Iron Oxide is not a good idea because it fluxes the glaze enough to run of the clay like a crystaline glaze. Separated yellow iron crystals form at 4% on a dark brown background. Copper Carbonate does not flux the glaze to a largely noticeable amount and turns the base pink at 1% with increasing flowering of green as you reach 5% until completely green. However, the copper doesn't melt the glaze past a satin in the 1% - 5% tests I did.

|

| MC Fake Nuka Base Flint - 30

Custer Feldspar - 37

Bone Ash - 2

Whiting - 23

OM4 - 6

Talc - 2

|

|

| Base 2A Cornwall Stone - 46 Whiting - 34 Flint - 20 |

|

| Base 1 Soda Feldspar - 65 Flint - 20 Whiting - 5 EPK - 5 Dolomite - 5 |

These white bases are all on the glossier side. The Fake Nuka shows signs of blue iron crystals forming from iron leaching from the clay body - small amounts of Red Iron Oxide (possibly .5%) would make a nice iron blue glaze. Base 2A crackles after firing (as apposed to during ) and thickness increases the strength of the crackle. The black ink on Base 2A is black Sharpie wiped directly after marking on with a wet paper towel.

|

| MC Tomato Red Flint - 15 Custer Feldspar - 30 EPK - 25 Whiting - 15 Bone Ash - 5 -------------------- Red Iron Oxide - 7 Tin Oxide - 1 |

|

| MC Copper Red Neph Sye - 45 Flint - 30 Whiting - 8 Spodumene - 17 -------------------- Copper Carb - 2 Rutile - 1 |

|

| MC Red Tenmoku Custer Feldspar - 77 Whiting - 6 Flint - 1 EPK - 4 Gerstly Borate - 13 -------------------- Red Iron Oxide - 9 |

My copper red glaze does not run very noticeably, unlike most oxblood variations. The Tenmoku does run, however, as you can see by the black pool. The running of what would normally be the dark body of a tenmoku glaze allows for the red to show.

|

| Shorn Base +2% Copper Carb Wollastonite - 25 Spodumene - 25 Cornwall Stone - 25 Talc - 25 -------------------- Copper Carb - 4% |

|

| Shorn Base + 2% Cobalt Carb and 1% Copper Carb Wollastonite - 25 Spodumene - 25 Cornwall Stone - 25 Talc - 25 -------------------- Cobalt Carb - 2% Copper Carb - 1% |

|

| Seafoam Custer Feldspar - 40 Whiting - 30 Flint - 15 EPK - 10 Spodumene - 5 -------------------- Yellow Ochre - 2 |

The Shorn base is very runny, just like other crystaline glazes, so be careful with both application and kiln shelf protection. Without colorants it is white on white. Copper Carb gradually changes the glaze from pale teal with lighter teal crystals (at 1%) to a more vivid teal with gunmetal crystals (at 5%). Cobalt produces a dark blue with purple crystals, Iron produces brown and yellow, Chrome produces green and green. Mixing of colorants should produce interesting color combinations between the crystals and the glaze matrix. Increased amount of colorants increases running.

|

| Satin Base +2% Copper Carb and 3% Rutile Custer Feldspar - 45 EPK - 25 Whiting - 15 Neph Sye - 15 -------------------- Copper Carb - 2% Rutile - 3% |

|

| Satin Base +2% Chrome oxide and 3% Rutile Custer Feldspar - 45 EPK - 25 Whiting - 15 Neph Sye - 15 -------------------- Chrome Oxide - 2% Rutile - 3% |

The Satin Base is a simple base the produces simple colors. Additions of Rutile or Titanium Dioxide increase the complexity of the coloring. This base also responds vividly to thickness changes, and doesn't run whatsoever. Less dull colors are easily obtainable by removing the rutile. The Speckled Base runs slightly and darkens where pooled. Change the colorants, but always keep the Tin Oxide as that is what produces the speckling.

|

| Glossy Frog Skin 1 Flint - 25 Dolomite - 8 Custer Feld - 55 EPK - 7 Borax - 5 -------------------- Copper Carb - 4% Cobalt Carb - 0.5% Red Iron Oxide - 2% Titanium Dioxide - 2 |

|

| Glossy Frog Skin 2 Flint - 25 Dolomite - 8 Custer Feld - 55 EPK - 7 Borax - 5 -------------------- Copper Carb - 2% Red Iron Oxide - 0.5% Titanium Dioxide - 3% |

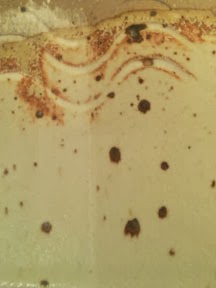

The Glossy Frog Skin Base is a nice glossy base on its own, but it responds well to excessive amounts of colorants - both by quantity of colorants and quantity of percentage of each colorant. Increased colorants enlarged the dotting of colors but also makes it run more. Without excessive colorants, the glaze doesn't noticeably run.

No comments:

Post a Comment